— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

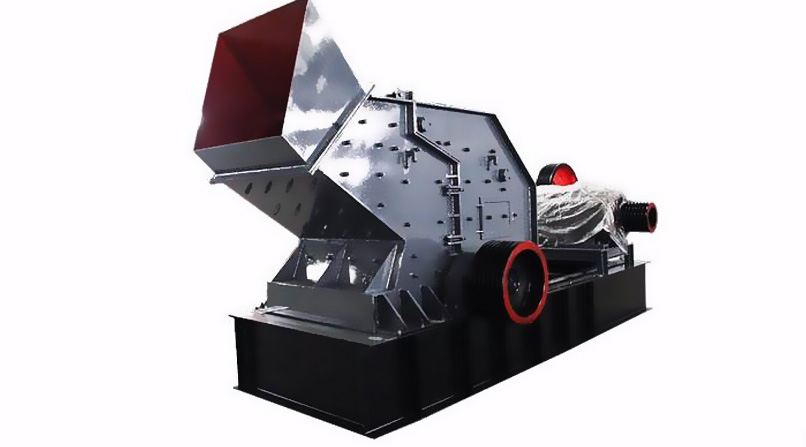

The hydraulic open-box sand making machine is improved from the "traditional sand making machine". Since the traditional sand making machine does not have a hydraulic power assist system, it generally takes two or three workers to disassemble the back cover, and the process takes about one or two hours. The introduction of the hydraulic open cover type sand machine solves this problem, one-click unpacking, not only replacement Hammer head, side plate and top plate are convenient, and can quickly solve the problem of material blocking! The whole process only takes 5 minutes, and the hydraulic unpacking sand making machine shortens the time of opening and closing the back cover by about 3-4 hours. Compared with traditional sand making equipment, it saves Save time and effort. What should I do if there is a blockage? Don't be afraid, 5 minutes after opening the lid, you can directly deal with the blockage of the machine. The whole process only takes about 10 minutes. The hydraulic unpacking sand making machine is a special equipment for producing sand and gravel for construction mainly from raw materials such as pebbles, granite, limestone and perlite. Compared with natural sand, the machine-made sand produced by the hydraulic open-box sand making machine has uniform particle size, excellent granularity and high compressive strength. Moreover, it is more in line with the requirements of high-standard construction sand than the sand produced by hammer crushing, and has an irreplaceable role in various fine ore crushing equipment.

|

Model |

Feeding |

Max. Feeding Size |

Discharging Size |

Adjustable |

Capacity(t/h) |

Powder |

|

|

Cement Clinker |

Limestone |

||||||

|

Φ800*400 |

400*185 |

<180 |

<5 |

0-30 |

20-30 |

30-35 |

37 |

|

Φ800*600 |

500*250 |

<180 |

<5 |

0-30 |

35-40 |

40-45 |

45 |

|

Φ800*800 |

550*330 |

<180 |

<5 |

0-30 |

40-45 |

45-50 |

45 |

|

Φ1000*1000 |

1000*350 |

<180 |

<5 |

0-30 |

50-55 |

65-75 |

55 |

|

Φ1200*1000 |

1200*400 |

<180 |

<5 |

0-30 |

65-80 |

75-100 |

100/110 |

|

Φ1200*1200 |

1200*450 |

<180 |

<5 |

0-30 |

75-90 |

90-110 |

110/132 |

|

Φ1400*1400 |

1500*500 |

<190 |

<5 |

0-30 |

90-130 |

110-150 |

160 |

|

Φ1600*1600 |

1600*550 |

<190 |

<5 |

0-30 |

180-210 |

190-250 |

250 |

|

Φ1800*1800 |

1800*800 |

<190 |

<5 |

0-30 |

250-270 |

280-310 |

315 |

Note:This specification is just reference,any changes are subject to the high-efficient fine crusher products.

High-efficient Fine Crusher Working PrincipleRelated Articles