— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

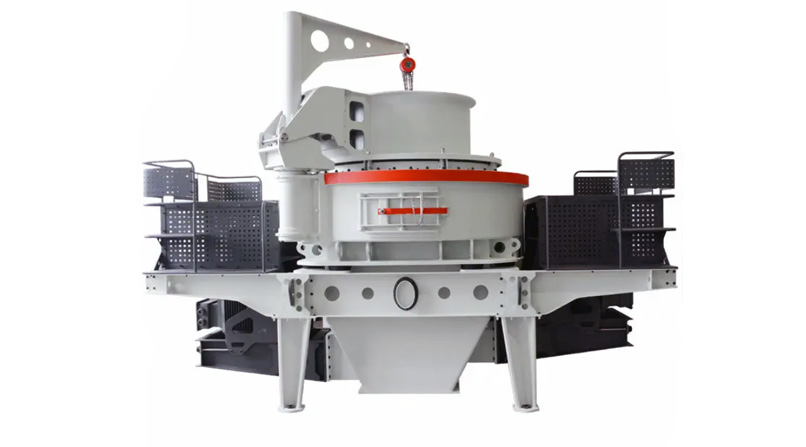

artificial sand making machine,6x series vertical shaft impact crusher is a new type of sand making and crushing equipment that absorbs many years of research and development experience and technical concept, adopts a new four port impeller design structure and special sealing structure to prevent oil leakage from the bearing barrel, and has a number of national patented technologies. It has the characteristics of energy saving, long service life and wide application, and helps the large sand field gradually move towards large-scale and centralized production, so as to meet the national requirements for environmental protection and production capacity.

artificial sand making machine,6x series vertical shaft impact crusher is a new type of sand making and crushing equipment that absorbs many years of research and development experience and technical concept, adopts a new four port impeller design structure and special sealing structure to prevent oil leakage from the bearing barrel, and has a number of national patented technologies. It has the characteristics of energy saving, long service life and wide application, and helps the large sand field gradually move towards large-scale and centralized production, so as to meet the national requirements for environmental protection and production capacity.

artificial sand making machine Scope of application

Metallic and non-metallic ores, building materials, artificial sand making, metallurgical slag

artificial sand making machine Material

River pebble, granite, basalt, iron ore, limestone, calcite, quartz, diabase, coal, calcium carbide, etc

The motor drives the main shaft of the transmission part of the bearing barrel to rotate at a high speed. At the same time, the rotor rotates at a high speed with the main shaft. The materials entering the impeller are accelerated by the impeller and sprayed into the crushing chamber. They collide and grind with the material lining materials formed in the crushing chamber. After the acceleration, the kinetic energy obtained by the materials is transformed into the energy required for crushing or shaping the materials. The materials circulating in the crushing chamber for many times are crushed and shaped for many times under the action of the surrounding gas vortex, The "crushing mode" is mainly applied to the "crushing" of the finished material from the lower part of the body, so as to form the stone required for shaping; In addition, the equipment is also equipped with a "stone beating iron" crushing method. Different from stone beating stone, the material is sprayed from the rotor and collided with the impact block installed in the crushing chamber to accelerate the energy obtained by the material into the energy required for collision and crushing with the impact block. After the impact, the material is discharged directly from the lower part of the body, which can not realize multiple cyclic crushing in the crushing chamber, This crushing method is mainly applicable to the workplace where crushing is mainly used (for the purpose of providing large crushing ratio).

| Model | Sanding making | Reshaping | Sanding making | Reshaping | Speed (r/min) | Power (kW) | Overall dimension (mm) |

| Maximum feeding size (mm) | Throughput (t/h) | ||||||

| VSI6X8015 | 30 | 40 | 109-117 | 131-210 | 1300-1700 | 75×2 | 4100×2300×2750 |

| VSI6X9026 | 35 | 45 | 167-179 | 200-323 | 1200-1500 | 132×2 | 4200×2400×3150 |

| VSI6X1040 | 40 | 50 | 264-283 | 317-515 | 1100-1400 | 200×2 | 4880×2560×3725 |

| VSI6X1150 | 45 | 55 | 344-368 | 413-663 | 1000-1300 | 250×2 | 5500×2750×3950 |

| VSI6X1263 | 50 | 60 | 454-486 | 545-872 | 900-1200 | 315×2 | 5700×2980×4190 |

| VSI6X1380 | 50 | 60 | 601-643 | 721-1150 | 800-1100 | 400×2 | 7900×3260×4183 |

| VSI6X13100 | 50 | 60 | 738-839 | 940-1510 | 800-1100 | 500×2 | 7900×3260×4183 |

Related Articles