— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

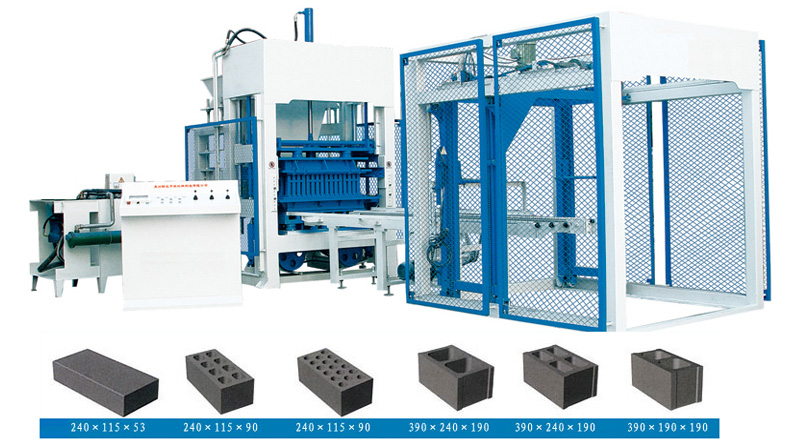

Concrete block brick machine can process many kinds of new type materials, for example: sand, stone, fly ash, coal refuse, cinder, slag, ore slag and pearl rock , Concrete block brick machine can made hollow building block, blind hole bricks and standardize bricks etc.

Special features Of the block brick machine:

1.reasonable designing, compact structure, directional vibration, brake with adjustable frequency, low energy consumption, no need to lie carrier by manpower, greatly reduce the labor intensity.

2.press from up and down, strong ramming strength, suitable to produce high strength block, and the products can be directly piled up to 35 layers after shaping.

3.it can produce various types of blocks with different moulds.

Technical Data Of Block Machine:| Product type | Specification size (long * wide * high) | Each modulus quantity (pieces) | Formation cycle | Productivity (daily output) |

| Hollow unit | 390*190*190mm | 4 | 13-30 seconds | 4000 |

| Sign brick | 240*115*53mm | 26 | 13-30 seconds | 25000 |

| Outlook size | Carrier size | Power | Weight | |

| 4300*1750*2300mm | 910*550*30(mm) | 15.5kw | 4.7T | |

| Product type | Specification size (long * wide * high) | Each modulus quantity (pieces) | Formation cycle | Productivity (daily output) |

| Hollow unit | 390*190*190mm | 4 | 30 | 2000 |

| Sign brick | 240*115*53mm | 26 | 30 | 15000 |

| Outlook size | Carrier size | Power | Weight | |

| 3000*2200*2900(mm) | 850*550*30-40mm | 15kw | 2t | |

| Product type | Specification size (long * wide * high) | Each modulus quantity (pieces) | Formation cycle | Productivity (daily output) |

| Hollow unit | 390*190*190mm | 6 | 13-18 | 11520 |

| Sign brick | 240*115*53mm | 32 | 13-18 | 61440 |

| Outlook size | Carrier size | Power | Weight | |

| 6525*1720*2550(mm) | 910*680*30(mm) | 19.05kw | 8T | |

| Product type | Specification size (long * wide * high) | Each modulus quantity (pieces) | Formation cycle | Productivity (daily output) |

| Hollow unit | 390*190*190mm | 8 | 13-18 | 15360 |

| Sign brick | 240*115*53mm | 40 | 13-18 | 76800 |

| Outlook size | Carrier size | Power | Weight | |

| 6225*2040*2470(mm) | 1100*700*30(mm) | 26kw | 9.6T | |

| Product type | Specification size (long * wide * high) | Each modulus quantity (pieces) | Formation cycle | Productivity (daily output) |

| Hollow unit | 390*190*190mm | 10 | 13-18 | 19200 |

| Sign brick | 240*115*53mm | 51 | 13-18 | 97920 |

| Outlook size | Carrier size | Power | Weight | |

| 8754*1880*2850(mm) | 1100*950*40(mm) | 36.5 kw | 18T | |

Related Articles