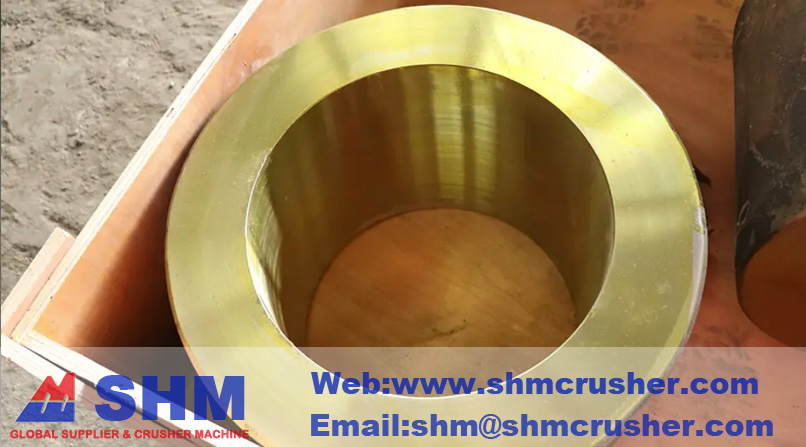

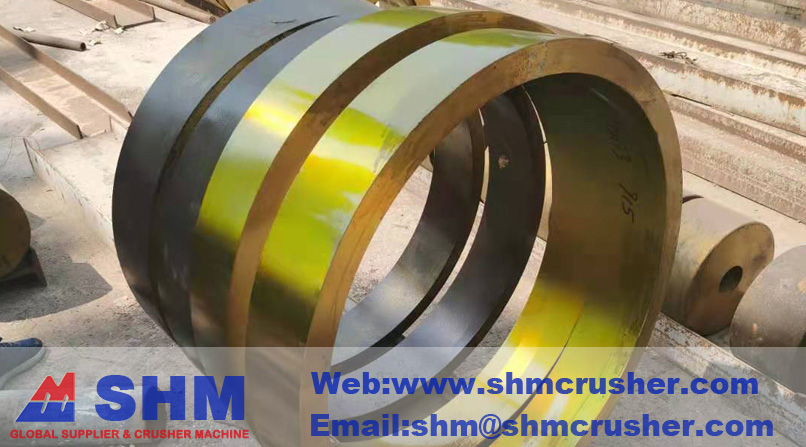

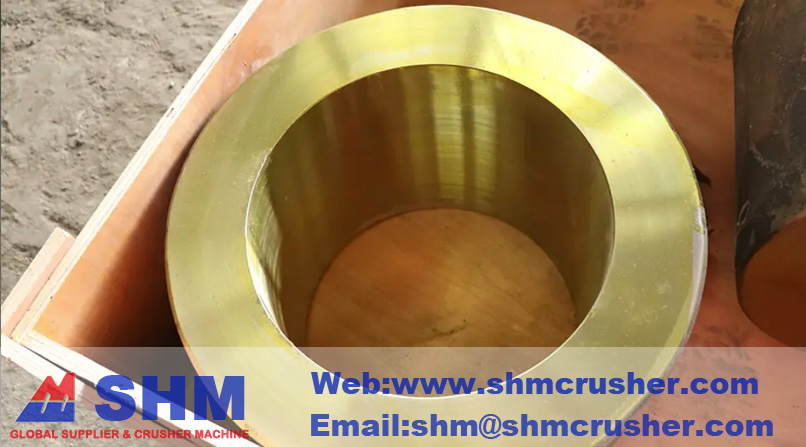

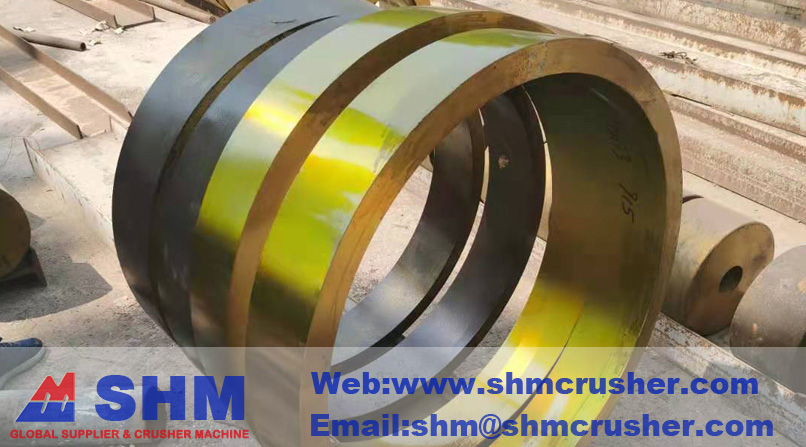

MTW175 grinding mill spare parts include roller,ring,roller setting,ectMTW175 grinding mill spare parts,SBM,Zenith,Liming MTW 175 grinding mill can grinder Feed particle size: 10-30 mm Production capacity: 1-30 TPHScope of application: calcium carbonate pulverization processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverizing, pulverized coal preparation, etc.Processing materials: limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz stone, bentonite, etc.MTM trapezoidal mill is a new type of energy-saving high-fine milling equipment that adopts trapezoidal working surface, flexible connection, and roller linkage pressurization. Mainly used in metallurgy, building materials, chemical industry, mining, highway, water conservancy and hydropower, refractory materials, steel and other industries, suitable for grinding various non-flammable and explosive materials with Mohs hardness below 9 and humidity below 10%. Trapezoid mill is composed of main engine, high-density powder separator, connecting pipeline, centrifugal induced draft fan, square box bag filter, crusher, bucket elevator, storage hopper, electromagnetic vibrating feeder, electric control cabinet, etc.

MTW175 grinding mill working principle

After the large block material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by the elevator, and then the material is uniformly and continuously sent to the main grinding chamber by the electromagnetic vibrating feeder for grinding. The pulverized materials are sent to the classifier by the air flow of the fan for classification. Under the action of the impeller of the classifier, the materials that do not meet the requirements of fineness fall into the grinding chamber for re-grinding, and the materials that meet the requirements of fineness pass through with the airflow. The pipeline enters the cyclone powder collector for separation and collection, and the finished powder is discharged through the discharge device. The separated airflow enters the fan through the return duct at the upper end of the cyclone collector. The system is a closed loop system and operates under positive and negative pressure.

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946