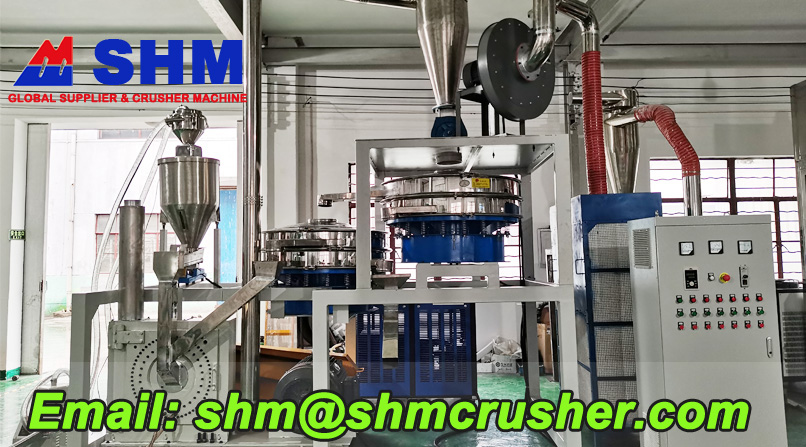

Processing materials:PE,PC,PP,PVA,PA,PS,EVA,LLDPE,ABS,PET,PEB,POM,PVC,SBS,TPU,Nylon,Resin, etc.

plastic grinder Product advantages

Can produce high-quality ultrafine powder

Nitrogen improves industrial safety

High energy efficiency, small footprint

Plastic grinder Technical characteristics

● The plastic grinder operates continuously and automatically.

● The plastic mill has compact structure and small floor area.

● The plastic grinder is integrated with steel structure, which is stable and reliable.

● The plastic grinder is easy to maintain and clean.

● Plastic grinding machine This machine can grind various soft and hard leather into fibrous shape at normal temperature: artificial leather, PVC, PE and other materials with different molecular structures into 10-300 mesh powder, especially suitable for plastic modification.

Performance characteristics

Full-automatic YOYONG series plastic pulverizer belongs to the disc type plastic pulverizer series, which is characterized by high output and low energy consumption, and is used for powder processing of polyethylene PE, polypropylene PP, polystyrene PS, ABS, EVA and other materials.

● The blade material of our equipment has a long service life, and the overall processing accuracy is excellent. A group of blades can be repaired for 6 to 8 times, and the later maintenance cost is low;

● Service life is more than 15 years;

● It is easy to install and maintain, and can be cleaned by opening the door cover;

● The grinding process is fully sealed, and the dust removal device is made twice, without dust leakage;

● High degree of automation and small floor area.

● The blade is made of high-quality imported steel with good wear resistance and is suitable for continuous operation.

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946