— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

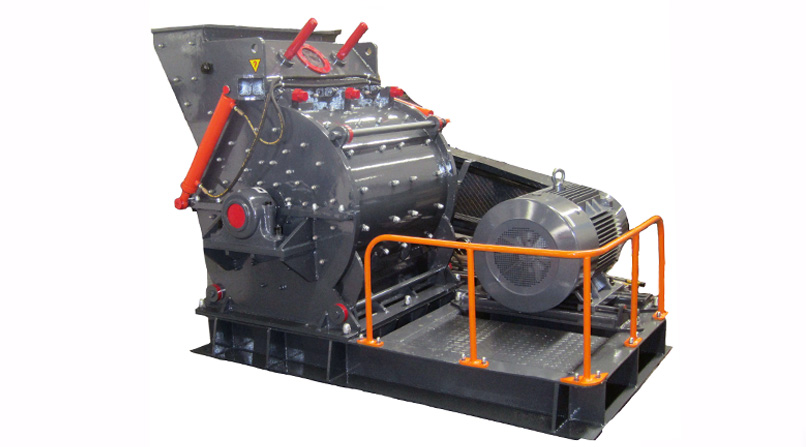

The European version of coarse grinding is mainly suitable for medium and fine crushing of various soft and hard ores whose compressive strength is not higher than 320MPa (megapascal), and is widely used in metallurgy, mining, chemical industry, cement, coal gangue, construction, sand making, refractory materials And ceramics and other industrial and mining enterprises. The European version of the coarse powder mill is mainly composed of the casing, the rotor, the bearing iron and the grate bar.

Coarse grinding mill Performance and Features

1. High capacity, big crushing ratio;

2. Low power consumption, uniform granularity;

3. Mechanical structure is simple, easy to use;

4. Investment costs less, more Convenient Management.

Technical Specifications of coarse grinding mill:

|

Model |

Rotor diameter |

Rotor length |

Rotor speed |

Feed head size |

Max feed size |

Fineness(mm) |

Processing |

Motor Power |

The number of hammer |

Dimensions L*W*H |

|

PC4008-75 |

750 |

800 |

800-1000 |

320×930 |

<50 |

0-3 |

10-30 |

55-75 |

18 |

2310*1665*1610 |

|

PC4012-90 |

900 |

1200 |

800-1000 |

400×1200 |

<50 |

0-3 |

30-60 |

75-90 |

32 |

2840*2100*2020 |

|

PC4015-132 |

1150 |

1500 |

550-800 |

500×1500 |

<100 |

0-8 |

60-100 |

110-132 |

32 |

3720*2650*2540 |

Note:This specification is just reference,any changes are subject to the Coarse Grinding Mill products.

Coarse Grinding Mill Working PrincipleRelated Articles