— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

Feed particle size: 10-150mm

Feed particle size: 10-150mm

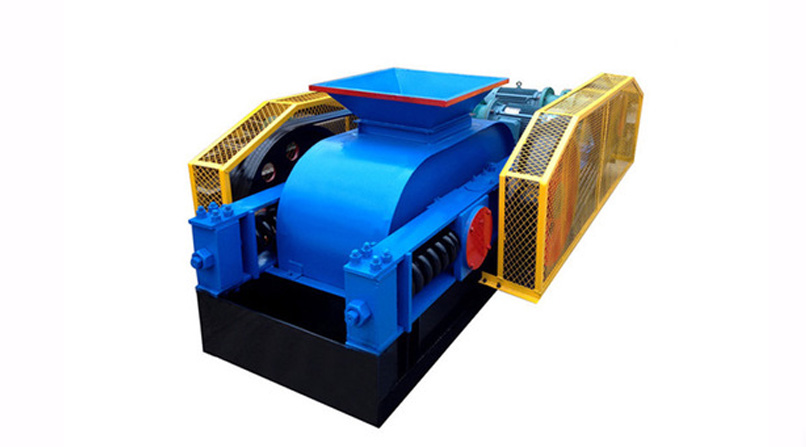

The pair (double) roller crusher is suitable for medium and fine crushing of solid materials with compressive strength less than 300Mpa and moisture content less than 35%. It can be widely used in mining, thermoelectricity, cement ceramics, metallurgy, chemical industry, Building materials and other industries have the characteristics of low maintenance costs, reliable performance, less dust, and low noise. The (double) roller crusher is equipped with two crushing rollers. According to the granularity required by the user, the roller surface is divided into two types: flat roller surface and surfacing roller surface. If the compressive strength of the material exceeds 200Mpa, the weighted model can be selected. . The flat roll surface model is suitable for fine crushing operations with a feed size of less than 80mm and a finished product size of 0.5-10mm. Such as the use of pebbles and construction waste to make artificial sand (sand); mining fine iron ore, quartz stone; ceramic industry crushing raw materials; metallurgical industry crushing coke, quicklime; coking plant fine coal powder, coke powder; chemical industry crushing various raw materials, etc. Or similar crushing occasions as above. The surfacing roller surface model is suitable for medium and fine crushing operations with a feed particle size of less than 150mm and a finished product particle size of 5-30mm. Such as pre-crushing cement clinker, limestone and composite materials before grinding in cement industry; pre-crushing coal before grinding in coal-water slurry industry; pre-crushing steel slag, iron ore and silicon ore before grinding in iron ore industry; ore to make non-burning bricks; thermal power plant crushing coal; or similar crushing occasions as above.

Roller Crusher advantages and features| Name | Model and size | Technical performance |

Motor power (KW) |

Outline dimension (L×W×H) (mm) |

Weight (Kg) |

||

|

Feed size (mm) |

Discharge size (mm) |

Capacity (m3/h) |

|||||

|

Double roller crusher |

2PG¢310×600 | <16 | 2-5 | 1.5-7 | 2×5.5 | 1750×2260×500 | 3600 |

| 2PG¢610×400 | <36 | 2-9 | 3-9 | 2×11 | 1785×2365×1415 | 3800 | |

| 2PG¢750×500 | <40 | 2-10 | 7-12 | 2×15 | 2720×2700×1400 | 10250 | |

| 2PG¢750×700 | <40 | 5-10 | 15-25 | 2×22 | 3422×2800×1705 | 11700 | |

| 2PG¢750×1000 | <40 | 2-10 | 6-30 | 2×30 | 4150×2800×1750 | 12500 | |

| 2PG¢900×500 | <40 | 2-10 | 9-30 | 2×22 | 2750×1790×2065 | 14000 | |

| 2PG¢900×900 | <40 | 2-10 | 11-45 | 2×30 | 2750×2180×2065 | 16800 | |

| 2PG¢900×1200 | <40 | 3-10 | 15-60 | 2×55 | 2750×2480×2065 | 20800 | |

| 2PG¢1000×800 | 25~90 | 3-40 | 12-50 | 2×45 | 2940×2080×2065 | 22600 | |

| 2PG¢1200×1000 | <40 | 3-12 | 10-50 | 2×37 | 3690×3430×2700 | 46820 | |

| 2PG¢1200×1200 | <40 | 3-12 | 18-68 | 2×75 | 3690×3630×2700 | 48600 | |

|

Four-roller crusher |

4PG750×500 | 30~60 | 2-10 | 3-10 | 18.5+17/11 | 2760×3585×2650 | 20800 |

| 4PG750×600 | 30~60 | 2-10 | 3.6-12 | 18.5+17/11 | 3390×2740×2650 | 21800 | |

| 4PG900×700 | 40~100 | 2-10 | 10-60 | 30+12/24 | 3150×4175×3147 | 28700 | |

| 4PG900×900 | 40~100 | 2-10 | 20-70 | 45+45/37 | 3150×4375×3147 | 31386 | |

| 4PG1200×500 | 50~120 | 3-10 | 30-90 | 75+55/40 | 9610×5600×4240 | 69000 | |

Note:This specification is just reference,any changes are subject to the roller crusher products.

Roller Crusher Structure and Working PrincipleRelated Articles