— PRODUCTS —

24 hours telephone +86-137-6117-8946

24 hours telephone +86-137-6117-8946 EMAIL:shm@shmcrusher.com

WhatsAPP:+86-139-1829-2742

WebChat:+86-189-1619-6140

Add:No.1998 Jinbi Road, Fengxian District, Shanghai,China.

TIME:2022-09-27

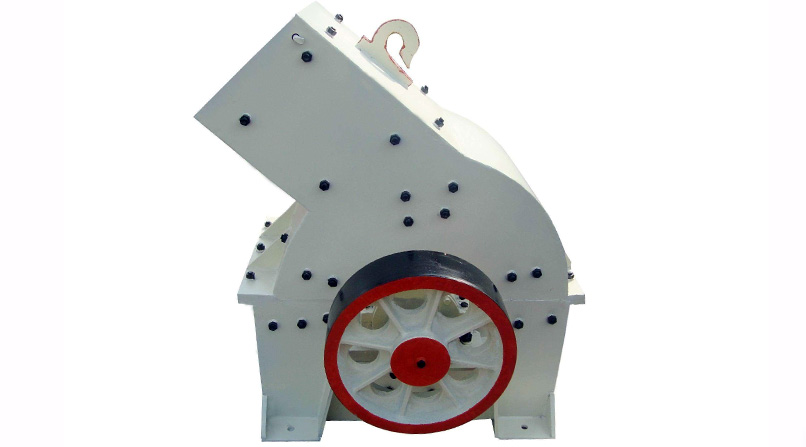

Hammer crusher (hammer crusher) is used to crush various medium-hard and weak abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. The crushed materials are coal, salt, chalk, gypsum, brick, limestone, etc. It is also used for crushing fibrous structure, strong elasticity and toughness of scrap wood, paper or crushed asbestos cement waste to recover asbestos fibers and so on. In addition, hammer crusher can not only be used in crushing production line, sand making production line, but also can replace cone crusher in mineral processing production line.

|

Model and size |

Feeding size |

Discharging size |

Capacity |

Motor Pole |

Powder (kw) |

Weight |

Overall Dimension |

|

PCΦ400×300 |

≤200 |

≤25 |

5-10 |

4 |

11 |

0.8 |

900×670×860 |

|

PCΦ600×400 |

≤250 |

≤30 |

10-22 |

4 |

22 |

2.26 |

1200×1050×1200 |

|

PCΦ800×600 |

≤250 |

≤35 |

18-40 |

4 |

55 |

4.8 |

1310×1180×1310 |

|

PCΦ1000×800 |

≤350 |

≤35 |

25-50 |

4 |

75 |

5.9 |

1600×1390×1575 |

|

PCΦ1000×1000 |

≤350 |

≤35 |

30-55 |

6 |

132 |

8 |

1800×1590×1775 |

|

PCΦ1250×1250 |

≤350 |

≤35 |

35-65 |

6 |

180 |

14 |

2060×1600×1890 |

|

PCΦ1400×1400 |

≤350 |

≤35 |

50-100 |

6 |

280 |

32 |

2365×1870×2220 |

|

PCΦ1600×1600 |

≤350 |

≤35 |

100-150 |

8 |

480 |

37.5 |

3050×2850×2800 |

Note:This specification is just reference,any changes are subject to the hammer crusher products.

Hammer Crusher Working PrincipleRelated Articles